Our expertise spans the full range of your metal component needs. With the combined power of our advanced machinery and extensive experience, we can usually complete orders within three to four weeks.

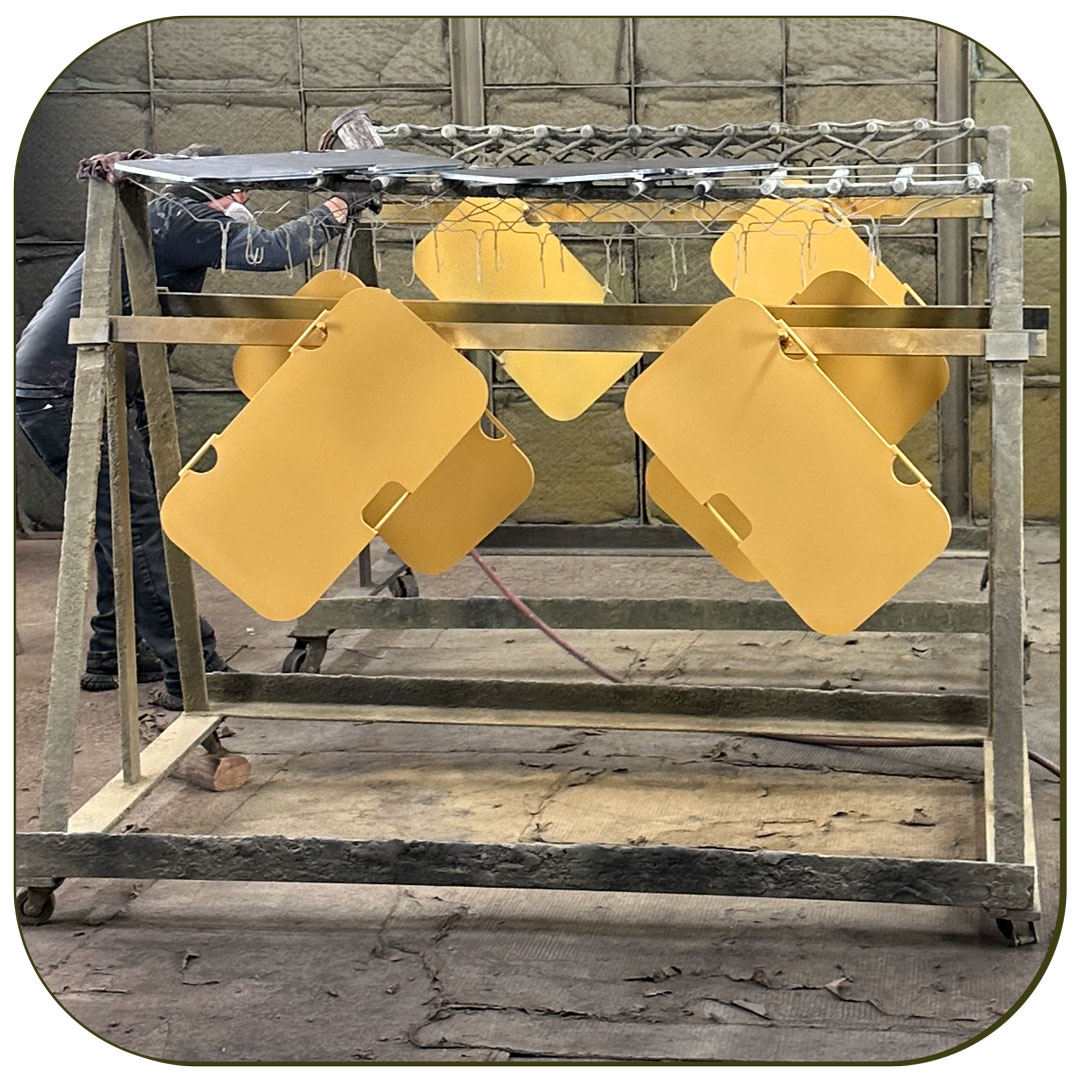

Whether it’s a ladder, handrail, or any other railroad equipment that needs painting, we can handle it. We accommodate a variety of items, regardless of size.

The powerhouse P140 Piranha Ironworker allows us to shear metal up to 1″ inch thick, and the blade permits accurate cuts with ease. We also use the Cincinnati ½ inch Shear and the 10 Ga x 10 ft Cincinnati Mechanical Power Shear.

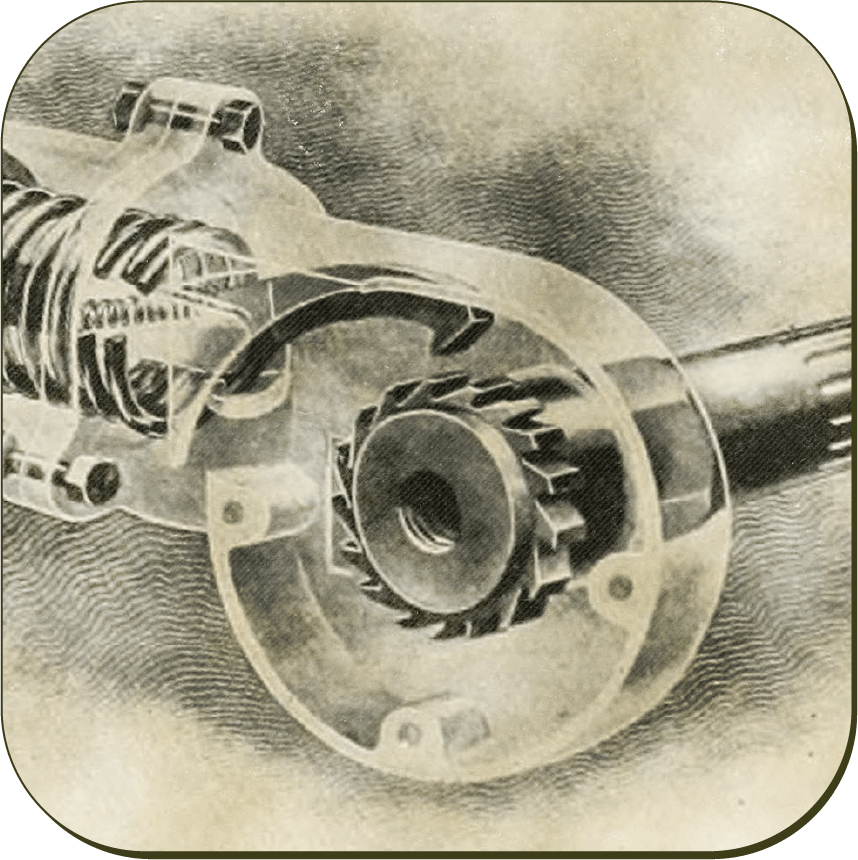

At Rail Exchange Fabricators, reconditioning old and damaged slack adjusters is part of the job. We take them apart, discard the damaged pieces, and reassemble them. Our process ensures you get a product that performs like new. You can send your broken slack adjusters for repair or purchase reconditioned Group E slack adjusters from our inventory.

We can make accurate and quality welds for handrail supports, load dividers, and more. Our team is especially experienced with stick and gas welding.

Rail Exchange Fabricators houses an impressive array of cutting-edge machinery. We’re equipped to deliver the perfect combination of speed, accuracy, power and finesse.

We participate in the Online Railcar Information and Scheduling System (ORISS) program to simplify ordering. You can track progress and receive order updates online 24/7.

Copyright 2024 Rail Exchange Inc.